HIGHEST YIELD THROUGH SUPERIOR TECHNOLOGY

THE NEW DIMLUX XTREME SERIES MKII

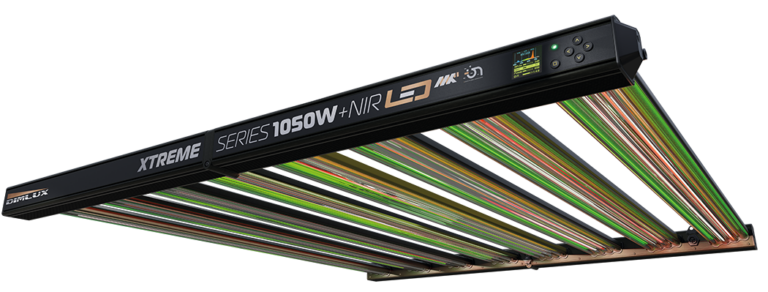

INTRODUCING THE ENHANCED DIMLUX XTREME SERIES MKII

UNRIVALED PERFORMANCE & NEW FEATURES THAT MAKE ALL THE DIFFERENCE

RESULTING IN THE HIGHEST POSSIBLE YIELD

HIGH QUALITY BUDGET FRIENDLY

THE NEW XPLORE SERIES 730W LED 3.0

THE NEXT GENERATION OF EXCELLENCE IN THE RENOWNED XPLORE SERIES.

CATEGORY-LEADING EFFICIENCY: 3.0 µmol/J FOR HIGHER YIELDS

ADVANCED LENS TECHNOLOGY: DURABLE AND DIRECTS MORE LIGHT TO CROPS

dimlux blog

CMH vs LED – The difference (and it’s BIG)

Choosing which technology is right for you depends on the size of your grow, how long you will be growing in the space, and your allocated budget.

Vapor Pressure Deficit – The Ultimate Guide

Learn how to create the best environment for your plants. We’ll explain the concept of Vapor Pressure Deficit in plain English for you. We’ll give you easy to use charts and a calculator too!

Guide to Photosynthesis – Light quality, intensity, and photoperiod explained

We’ll tell you about the key elements that make photosynthesis work best for your plants. Things that matter, like light quality, spectrum, intensity, and photoperiod. Want to know more? Read on…

GET ON BOARD

Send us your information and we’ll be in touch right away. White glove service that you expect from the best.